Artificial intelligence (AI) is worming its way through global industries in everything from fast food production to farming to energy grids and water treatment plants. It also now touches almost every aspect of the auto industry including design, engineering, manufacturing, employee interactions, marketing and sales.

Broadly, it saves automakers money. More specifically, AI is changing the way cars are made, and how the public interacts with them.

Generative AI, which creates new content and data (as opposed to traditional AI that solves specific tasks with predefined rules), is expected to lift marketing and retail sales productivity by more than $950 billion, according to a McKinsey report.

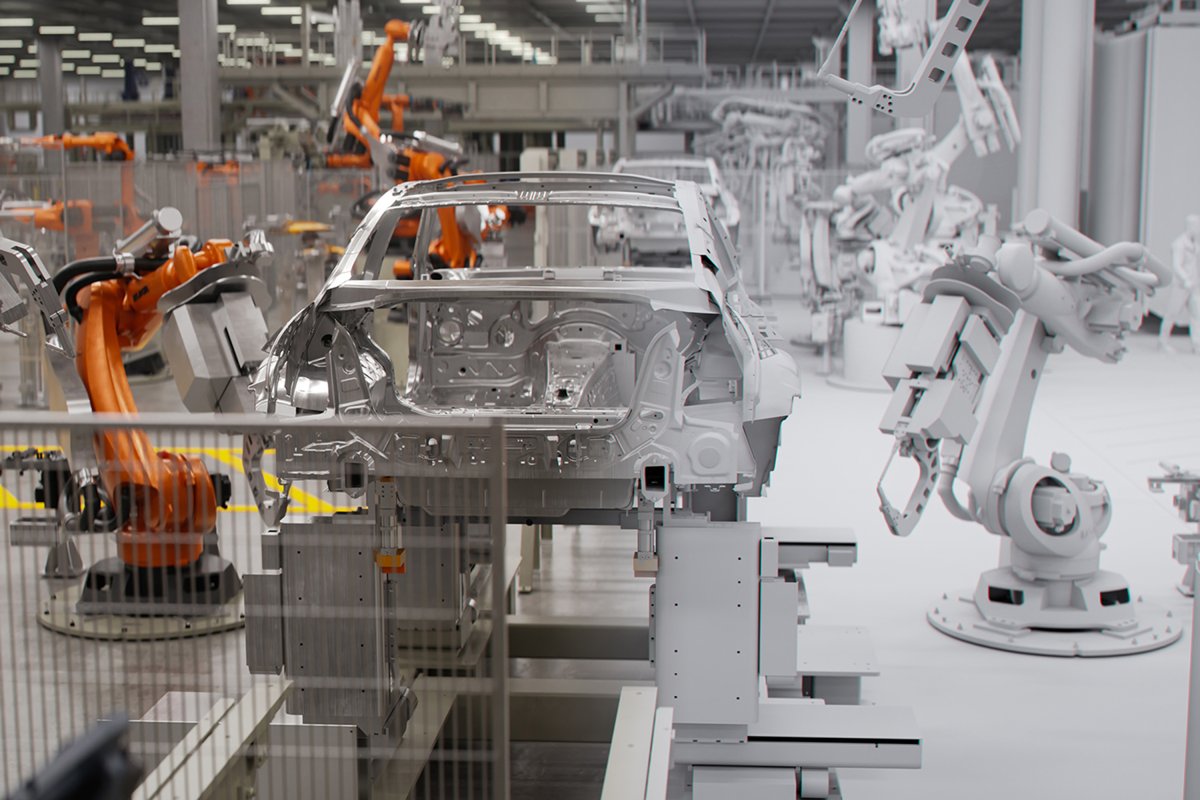

Mercedes-Benz and BMW are using generative AI to redesign old manufacturing plants and create new ones.

Mercedes-Benz used AI software to create a "digital twin" of its plant in Kecskemet, Hungary, including the infrastructure, breakrooms and bathrooms. Using that twin Mercedes can plan how new assembly areas can be added, how old ones can be retooled and how it will affect walkways and fire protection. The company can do that will less interruption of the current plant operations.

The process increases the speed, transparency, and flexibility of the changes before installing the hardware. Mercedes says it can reduce coordination processes by 50 percent while doubling the speed for converting or constructing an assembly hall. Quality is improved as the data is collected in the virtual world, catching potential errors earlier.

In the paint shop at the Mercedes Rastatt plant in southern Germany, AI took over the monitoring of the paint sub-processes leading to energy savings up 20 percent compared to how it was previously done. Mercedes says the AI control of these processes will be rolled out to other plants and departments.

BMW is using AI not only to design its new plant opening in Debrecen, Hungary in 2025. It's also testing what production will look like once it starts. It's using Nvidia's Omniverse platform to optimize the layout and robotics that will build the company's next generation of electric vehicles.

This keeps the company on the road to the BMW iFactory, a concept it introduced in 2022 and described as the "automotive production of tomorrow." It started three years ago when all of the BMW's plants and vehicles were 3D scanned. It has scanned more than 2.7 square miles of indoor locations and 5.7 square miles of outdoor space so far. Modifications can be updated with a re-scan at any time.

BMW already has a digital twin of its Spartanburg, South Carolina plant, it's main plant in Munich and at Regensburg. Those plants can be inspected virtually, and individual sections can be cut out and sent to suppliers so they can reduce planning errors.

At the body shop in Spartanburg, between 300 and 400 studs are welded to each car body, which provide alignment points for everything from bumper brackets to electronics. They need to be placed perfectly and are measured 12 times each by laser radar technology.

"With about 1,500 cars produced each day, this means hundreds of thousands of studs are installed daily and need to be meticulously maintained. This method required substantial time and effort to ensure dimensional quality. The benefit of using AI resulted in a 95 percent efficiency improvement. Now dimensional team members can use their worktime more efficiently and concentrate on more complex tasks," Matt Cornelius, Metrology Automation Engineer and Project Lead for AI Stud Correction, BMW Manufacturing told Newsweek.

Toyota's use of AI started in 2016 with plans for a cloud-based safety system. That became Safety Connect, which used sensors to figure out when a crash occurred and immediately sent a notification to a call center, who would call rescue services if necessary. Over the same time period Toyota was honing its voice-activated Virtual Agents that respond to "Hey Toyota" or "Hey Lexus." Those assistants can now take commands for audio, climate control and other functions.

AI enhancements are also helping owners keep up on their maintenance schedules with data models on common items like oil, battery, brakes and tires. It checks one car's wear against the millions of other connected vehicles and predicts when you need to head into a dealership, "prior to component failures," according to Toyota.

In September the Toyota Research Institute announced a breakthrough using generative AI to teach robots complicated new skills. It wants to build a "large behavior model" for robots equivalent to the large language models chat AI programs are using.

The skills include traditionally difficult things for robots to do like pour liquids, use tools and manipulate soft objects. So far it has taught custom-built, dual-arm robots more than 60 difficult skills and is targeting 1,000 by the end of 2024.

"The ability to quickly teach new skills will allow us to use robots in applications that have traditionally been difficult or impossible to automate. We could now imagine robots that could work alongside people, helping them to replace fluids, wipers, filters, lights, wire harnesses, and/or deal with other difficult-to-model materials," Russ Tedrake, VP of robotics at TRI told Newsweek.

"But there are still basic research questions that must be addressed — if we can teach enough skills to create a broadly capable robot, then we might unlock an entirely new level of competence and robustness that will make robots more useful both in traditional applications and applications we haven't even dreamed up yet."

Toyota has also been using AI with its voice assistant and maintenance data (engine and transmission oil life, coolant level) for years and is now using it to teach robots how to make human-like movements. Every future vehicle with autonomous driving will use some form of it, and it has even entered the boardroom.

Automotive marketing teams are using large language models (LLM) to brainstorm and get feedback, in addition to image generators for advertising campaigns. Nvidia, a technology company that designs software and hardware, including complete AI language and image models, is helping marketers create personalized visual content more efficiently and faster than they could before.

Uncommon Knowledge

Newsweek is committed to challenging conventional wisdom and finding connections in the search for common ground.

Newsweek is committed to challenging conventional wisdom and finding connections in the search for common ground.

About the writer

Jake Lingeman is the Managing Editor for the Autos team at Newsweek. He has previously worked for Autoweek, The Detroit ... Read more

To read how Newsweek uses AI as a newsroom tool, Click here.