Excitement over 3-D printers that will someday magically "print" a toaster or an Armani suit in your den reminds me of my father telling me, in the 1960s, that we'd all soon be driving atomic-powered cars.

Both predictions fall into the same category: plausible bullshit.

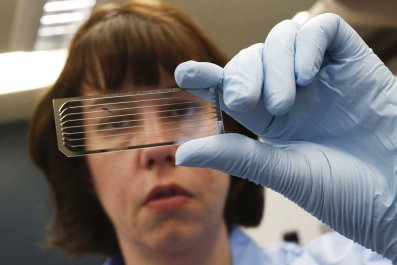

That said, 3-D printing is starting to do something amazing. The technology is transforming physical stuff into data, much the way digital technology over the past 20 years changed things like newspapers and phone calls into data.

Once anything turns into data, it becomes cheap and easy to send anywhere over networks, and cheap and easy for anyone to manipulate using software. So imagine a world where physical stuff—chairs, shoes, sex toys, Jeeps—can be sent around the world instantly and at almost zero cost. And imagine a world where the design of those chairs, shoes, sex toys or Jeeps could be altered and customized by any suburban mom on her iPad while fighting boredom at her kid's soccer game.

Importantly, though, we're not talking about printing those final products at home. The foreseeable future is more about products printed and assembled near your home by a business that can afford industrial-grade machines. In a way, these printed products will be like french fries: Sure, you can install a deep fryer and make fries in the kitchen, but it's a whole lot simpler to just go to McDonald's.

As physical stuff becomes data, one of the first big impacts will be in spare parts. Just think of the enormous waste of time, space and energy devoted to spare parts. For every item ever sold that's even modestly expensive—cars, computers, factory robots, hot water heaters—buyers expect to be able to get parts into perpetuity. The U.S. auto parts market alone will be $141 billion this year. Plastic knobs, metal casings, hoses, connectors, wheels and so on fill warehouses all over the world, sitting there waiting for something to break.

3-D printing will change that. Parts will become data—designs sitting on computer systems. When a part breaks on your dishwasher, maybe you'll go to Home Depot, where the clerk downloads the item and prints it right there. Auto dealers could do the same for cars. No more waiting days for your Volvo part to arrive from Sweden. This change will start with one-piece plastic parts, but before long will move to metals and more complex parts that require printing several pieces that fit together. Warehousing most parts will go the way of stamping music onto CDs—unnecessary and inconvenient.

Another effect of turning stuff into data will be mass customization. You may never again have to own anything that looks like anybody else's.

Shapeways is one of the upstart 3-D printing companies going down this path. Anybody can design a product and upload it to the Shapeways site. So far, most of the items are pretty simple and craftsy—teacups ringed with teeth, pendants that look like headphones. None of the products are made in advance. When someone clicks to buy that toothy mug, Shapeways then prints and ships it, and shares the profit with the mug's designer. Until there's an order, all Shapeways products are just data.

Because the products are data, they don't have to be static. The designers can constantly tweak them in response to customer input. "It's iterative—I've seen some products go through 30 versions in a couple of months," Shapeways CEO Peter Weijmarshausen said at New York's Internet Week 2014.

Maybe more significant, customers can design their own thing. Weijmarshausen points to mounts for GoPro sports cameras. People want to attach GoPros to everything from their dogs to hula hoops, so they go on Shapeways and customize a mount and get it printed. "Everybody's empowered to solve their own problems," he says.

Industrial-scale 3D printing will get increasingly sophisticated, rendering one physical thing after another into data that can be sent anywhere, modified by anyone, and printed and assembled locally. In another decade, shoes, chairs, bicycles or who knows what else will become data. "We'll have a world of entirely bespoke items," says futurist Paul Saffo.

There's an industrial side to this, too. This process is going to open up physical-product industries the way the Internet and blogs opened up the business of news. Even the Obama administration is all over this. On June 18, it hosted its first White House Maker Faire, noting, "New tools for democratized production are boosting innovation and entrepreneurship in manufacturing, in the same way that the Internet and cloud computing have lowered the barriers to entry for digital startups."

General Electric executive Stephen Liguori likes to talk about a jet engine bracket GE decided to crowd-source and 3-D-print. GE posted the requirements online and let anyone submit a design. GE hoped for ideas that would take 30 percent of the weight out of the bracket. An engineer from Central Java in Indonesia won the challenge, slashing nearly 84 percent of the weight. GE could just download his design and print it out of steel and titanium. "We got 697 designs from incredibly smart people we'd never have found," Liguori says.

That scenario will play out over and over. If a garage startup circa 2020 wants to develop a new lightweight lawn mower, it might set up a 3-D printer, download the best parts designed by people all over the world and create a lawn mower essentially out of data. Then the startup wouldn't have to manufacture an inventory of lawn mowers; the company would only print and assemble a lawn mower when someone ordered one. The possibilities for entrepreneurs will be endless.

It's not that people won't have 3-D printers at home. However, "the most visible 3-D printer—the one everybody could have in the house—is the least important," Saffo notes.

So we'll get developments such as the $149 home 3-D printer from startup New Matter. And we'll get the attachment that lets a home 3-D printer print in Nutella. And of course the porn industry, which always embraces new technology ahead of the curve, will find ways to let you make an instant replica at home of any body part you happen to be admiring on-screen.

But all in all, the home 3-D printer that conjures up objects like Samantha on Bewitched will succumb to the plausible bullshit principle: sounds real but isn't. 3-D printing's greatest trick will be the way it turns atoms into bits.