On a balmy May night at Yankee Stadium in New York, nearly 50,000 fans rush from their seats after the Yankees? 5?3 loss to the Pittsburgh Pirates. They stream out of the stadium, down the ramps and onto the streets. Their seats may be empty but they leave plenty behind: souvenir cups half-filled with soda and beer, soggy wrappers, cardboard boxes and tubs holding the greasy dregs of a ballpark dinner. This all-American waste is tough to clean and, worse, it traps bacteria and other unhealthy organic matter, creating a veritable ?mould bowl? that can last all season long.

One company may have a solution. Pureti, a ?distributed? organisation has designed, tested and is now marketing a suite of spray-on products made with titanium dioxide (TiO2, known as titania) that, it says, can transform any surface into a self-cleaning dynamo that not only kills microbes but lowers air pollution in the vicinity. Glen Finkel, Pureti?s CEO, insists that it is first and foremost a healthcare company. He believes widespread use of their products would vastly improve public health by lowering pollution levels outside, and making air healthier to breathe. But, as a businessman, he knows health doesn?t sell. So he?s offered companies something much closer to their hearts (and bottom lines): the ?hard ROI? ? business lingo for ?return on investment? ? of cost-savings on weekly cleaning bills.

Pureti wants to start by making clients of some of the modern world?s most hallowed sports grounds. So far, it has hooked one major US sports venue: Sun Life Stadium in Miami? a 25-year-old coliseum that holds 75,000 fans per game ? and the detritus they create. ?Between the heat, and the humidity, and the beer, the people maintaining the stadium had to powerwash after every football game,? says Finkel.

According to John Kennedy, vice president of operations support of DTZ (the stadium?s facilities management company), cleaning a football stadium costs between $60,000 and $90,000 a game, and it wastes a whole lot of water. So Finkel took some Pureti products down to Florida last season and gave DTZ a test drive: they chose a small section of the stadium floor, covered half of it with Pureti and left half untreated, as a control, through an entire football season. Within weeks ?it was clearly evident? which rows of seats were in the control group and which had been treated with Pureti, says Kennedy. ?All it would take is one day of sunshine, and one aisle would snap back to being clear and clean, and the other would dis-colour, and you?d see evidence of mould accumulation. We?d have to pressure wash the untreated row more aggressively and more often than the untreated row.?

In March this year, DTZ had Pureti coat the entire stadium with its spray, which Finkel says will last for at least five years. Other stadium managers are starting to hear about the company. Pureti was asked to bring their product to Camp Nou in Barcelona. They haven?t yet coated that centerpiece of Catalonian athletics, but Finkel expects it to happen sometime in the coming year. He says there are rumblings that they?ll be asked to work on the 2018 World Cup. The truth, though, is that the whole notion of ?self-cleaning? is really just a subterfuge to get the pollution-lowering technology into and onto as many buildings as possible.

This promises to be the game-changing technology we?ve all been waiting for. It?s got all the right buzzwords. Nanotechnology. Air-Purifying. Antimicrobial. Green. Sustainable. And best of all, it can save the planet without having to give up cars, spending hundreds of dollars on ?locally sourced? organic food, or feeling bad about buying a new iPhone every two years. Just spray Pureti?s proprietary titanium dioxide-based liquid all over windows and walls, and pat ourselves on the back: we?re turned our homes into a self-cleaning, pollution-eating machine.

Pureti?s liquid gold is being slathered elsewhere: the caretakers of La Pedrera, a Gaudi-designed building and Unesco World Heritage Site in Barcelona, are using it to keep mould from growing in the structure?s complex crevices. Hotels from the Bahamas to Qatar use it in their luxury suites to manage odour and improve air quality. London is considering a citywide programme to apply it to public buildings in order to get levels of NOx (mono-nitrogen oxides that cause ozone) down to acceptable levels (the UK was recently forced to reduce pollution levels by the European Union Supreme Court). Nasa is testing it for use on solar panels: if the panels stay cleaner longer, they stay at their highest level of energy efficiency ? and it?s much harder to clean surfaces floating in space than those down on Earth.

Finkel?s pet project, though, is with the Asthma and Allergy Prevention Company, which is applying Pureti as part of a protocol for transforming regular homes into hospital-grade environment so that children with serious respiratory issues can stay out of the emergency room. I

t is currently in the Food and Drug Administration approval process; if the federal regulator gives the thumbs-up, Pureti could soon be considered a health product.

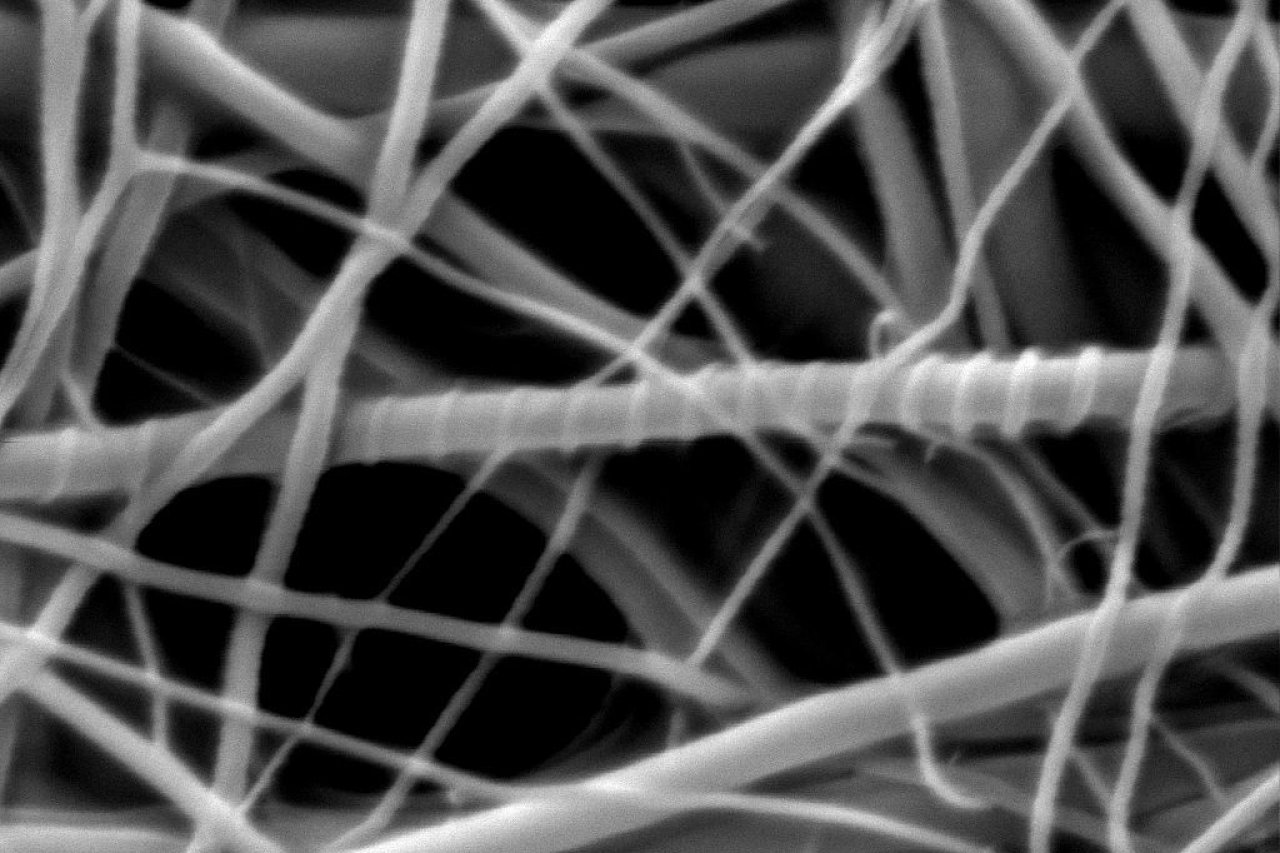

If you want to know how it works, look around. If you?re anywhere indoors, chances are your glance passed over at least one painted surface containing titanium dioxide. Titania pigment is the whitest of whites, with a brightness and ability to refract light that is unmatched in the world of material sciences. The stuff shows up in products as wide-ranging as ink, toothpaste, cosmetic products, sunblock and plastics, and there?s a whopping pound and half of titania in every gallon of paint. It?s common and it?s cheap: titanium is the ninth-most abundant element in the Earth?s crust.

It does have its flaws. A coat of a regular titania pigment-based house paint will eventually start to crack and peel when exposed to the sun. For years people didn?t know why until two Japanese researchers at the University of Tokyo, Kenichi Honda and Akira Fukishima discovered that the white pigment ? the titania ? was doing something called photocatalysis.

Simply put, titania uses light to speed up chemical reactions around it: ultraviolet rays (from the sun or from artificial light sources) hit the surface of an object that has been covered in titania, and that triggers a chemical reaction in which water molecules (that come from moisture in the air) are momentarily split into hydroxyl radicals (known as free radicals). Then, these hydroxyl radicals quickly seek out any organic matter touching that surface and break it down into smaller molecules.

That?s a bad thing for a white-washed fence, but a good thing for planet Earth. For the most part, the organic molecules in the air tend to be dangerous for humans, the environment or both.

The air is loaded up with matter like volatile organic compounds (VOCs), which cause all sorts of terrible health effects, NOx, and grime (which makes things dirty, and attracts disease-carrying bacteria).

Photocatalytic titania cuts the stuff down. ?The idea is that you convert VOCs into carbon dioxide and water, and you convert NOx in the air into something like nitrate that would just wash away,? says Jonathan Raff, professor of environmental science and chemistry at Indiana University. ?All these things would just go away, and you wouldn?t have a smog problem.?

Honda and Fukishima?s discovery made more than 40 years ago in 1967, was truly groundbreaking ? the two men are by some accounts currently on the short list to receive a Nobel prize. So where has it been? If the stuff is so miraculous, why don?t we all know about it?

If Pureti and a few other companies have found ways to make crystal clear titania coatings; why isn?t every building we work and live in, and every material good we own covered in titania?

?TiO2 has been studied to death,? says Alexander Orlov, a materials science and engineering professor at Stony Brook University. ?There are still some scientific issues to address, but the fact that it works has been confirmed by many research groups.?

Orlov and Raff have both published papers showing that as part of the chemical process that occurs during photocatalysis, dangerous molecules can be temporarily created. ?[VOCs] get partially oxidised,? says Raff, ?which means they might form aldehydes or oxidised versions of the molecules.? Both of those are bad for the human body, if they stick around. But Orlov, who spent seven years advising the British government on the safety of nanotechnology and hazardous substances argues that overall, the process is a net positive ? it?s getting rid of lots more bad stuff than it creates.

?These papers just show one of the elements, and one of the possible reaction pathways,? he says. Taken in the bigger context, this is just small potatoes. Orlov points out that there are the same issues in chlorinated water ? the chlorination process creates dangerous intermediaries along the way to generating healthy drinking water.

According to Orlov, the biggest problem with photocatalytic titania is actually the marketing. The first attempts to bring titania to the market were in 1998, when the four largest glass manufacturing companies in the world all simultaneously launched ?self-cleaning?, photocatalytic glass. UK-based Pilkington, for example, created and heavily marketed a product called Activ. Neil McSporran, a civil engineer by training and the current manager of business development at Pilkington North America, says Activ has sold well enough in the UK and Canada, but in the US sales have been disappointing. That?s why they are abandoning the ?self-cleaning? rhetoric: they?re going green.

?One thing we?ve been revisiting is how we can change our message,? says McSporran. ?What?s become more important than the easy-clean element is the degradation of harmful pollutants.? According to McSporran, over the past few months, internal company discussions have centered around ways to make the science their key marketing message. Finkel says Pureti had been working on this product for years without getting any traction, in part because potential clients thought it was too good to be true. ?That was a big albatross around our neck,? he says.

In Japan, by luck of historical confluence, the marketing problem solved itself. In 2001, a Japanese ceramics company took titania nanopowders, and melted them into a glaze for tiles. The tiles were used in schools and hospitals throughout the country. A year later, a previously unknown viral respiratory illness spread rapidly through Eastern Asia.

The disease, severe acute respiratory syndrome, which became widely known as SARS coronavirus, eventually infected 8,096 people worldwide, killing 774. Most of the stricken were in China, Hong Kong and Taiwan, but the virus reached Thailand, Vietnam, Singapore, and the Philippines ? not to mention Canada and the US. Twenty-nine nations saw one of their citizens fall ill.

But not Japan. Even though the country was close to the epicentre of the disease, SARS never made it to its shores. And when the tiles were found to inhibit the spread of SARS (and other viral and bacterial diseases), Honda and Fukishima became hometown heroes. Titania in Japan is quite literally a billion dollar market. Companies including Toyota, Panasonic, Fujitsu and Bridgestone all maintain significant brand currency from the aura titania provides, and windows, walls, and even roads are coated in the stuff.

There?s nothing nearly as impressive going on in the rest of the world. Pureti?s R&D lab is a small outfit, not much more than a garage in a business park in suburban Connecticut. There, two scientists, senior chemist John Andrews and director of technical operations Bikash Rajkarnikar, mix new product batches in equipment a good high school chemistry lab would have.

They run tests on sample materials sent in by potential clients and try to figure out what other great things their product can do. They?re also trying to figure out how much photocatalytic titania really clears the air: they have a small metal chamber the size of an office cubicle that they fill with VOCs, then they stick some Pureti-coated glass inside, along with an $8,000 VOC sensor, and see what happens. The results are signs pointing in the right direction ? the air is cleaner post-Pureti.

These experiments, though, have been done before. Finkel and his team regretfully admit they have a problem: there?s really no way to test titania in the real world. It?s just too complicated, and too big.

?When it?s cleaning up air, it?s cleaning up air for the entire globe,? says Orlov. ?All of the studies have been in laboratories,? adds Raff. ?The real verdict has to come from real, in-the-field, outdoor studies.?

It?s easy enough to figure out what happens in a small, controlled space, but cities are complex beasts; Orlov says that atmospheric science has only a ?rudimentary knowledge of the impact of building materials on urban air quality. It?s the next frontier.?

An hour and a half south of the lab is Finkel?s office, a modest space in a narrow building crammed into a lively block in Manhattan?s financial district. Finkel, in a former life, was a practicing psychologist (?He reads people very well,? says Orlov), and he knows how to guide the conversation. He?s there to convince you that his product can save the planet.

If only you?d agree, you could help him save the planet, too.