It's a common marketing ploy built off of basic physiology: When a medicine absorbs easily into the body, we get comfort faster. So when we're sick and in the pharmacy, we tend to reach for medicines that promise rapid relief.

On the horizon are even faster acting meds. In what was initially considered an accident, University of Michigan engineers have created smooth, rounded crystals that, of their several applications, may set the stage for 3-D-printed medications that are absorbed better by the body. The findings appear in the journal Nature Communications.

The "nanolobe" structures were discovered in 2010 by Shaurjo Biswas, who at the time was a doctoral student at the university. Biswas was working on creating solar cells (the devices that capture energy from sunlight) by using organic vapor jet printing—a form of 3-D printing that resembles spray painting with a gas. The printer creates layers of films made up of faceted crystals that, under a microscope, look like cut jewels. One day, Biswas was examining a newly printed layer of material when he noticed a repeating pattern of strangely rounded crystals that seemed, at first, to be a machine malfunction.

Luckily for the world of material science, a team of UM scientists and engineers kept looking at the nanolobes, as they decided to call them, and discovered these rounded crystals could be used in a variety of applications. For example, coating LEDs with the nanolobe film could make them more energy-efficient—the crystals would guide light in an organized way.

"In LEDs, one of the big problems is that a lot of the light generated is trapped inside. The structures we're able to print could really help improve the efficiency of getting those photons to come out, making LEDs more efficient," Max Shtein, associate professor of materials science and engineering at the University of Michigan, told Newsweek in an email. Preliminary findings also show the nanolobe film, when sprayed on glass, metal or plastic, can make these surfaces liquid-repellant and self-cleaning.

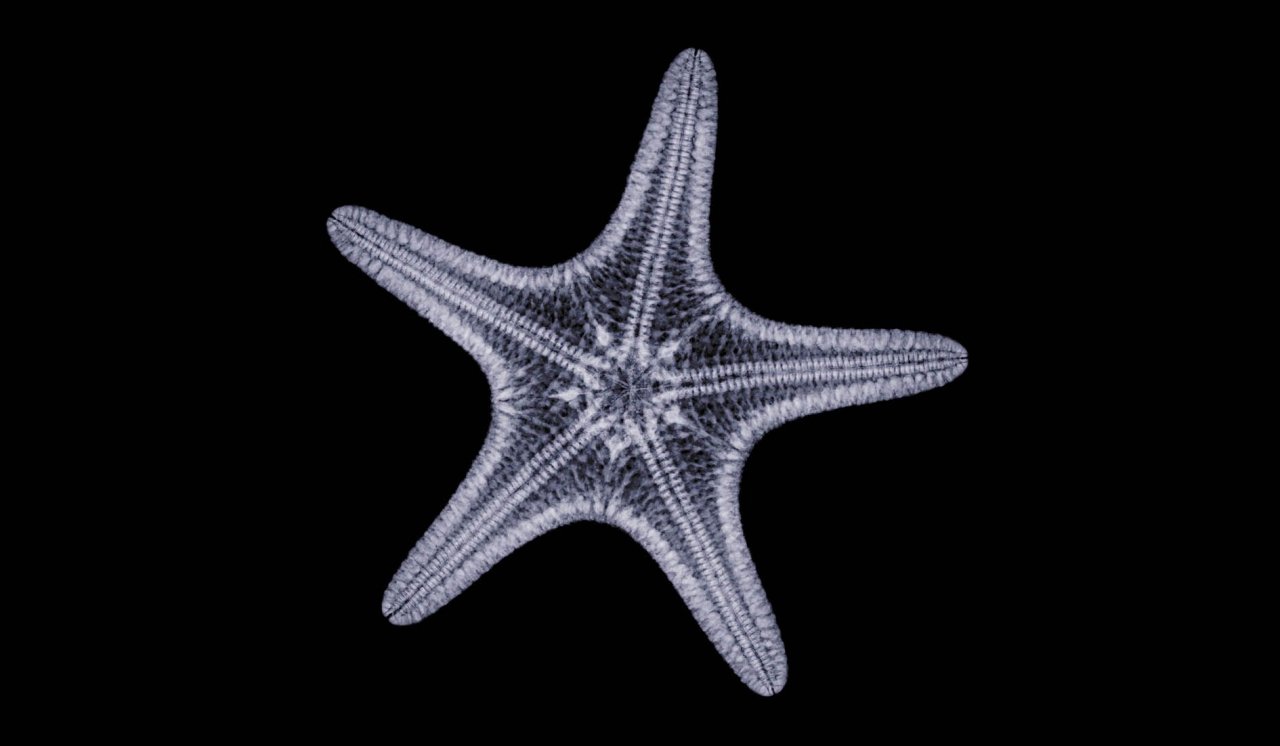

But perhaps most exciting, the nanolobes could be used to create highly efficient, personalized-dosage, 3-D-printed medication. The nanolobes consist of well-ordered molecules and researchers are able to exactingly manipulate these conditions with the vapor jet printing system. In theory this could allow them to create pills with a high surface area—that would dissolve much faster in the body than the standard compressed powder tablets—and with very precise amounts of the drug's active ingredients, perhaps tailored to individual patients.

It's too early for researchers to identify specific drugs that could benefit from the starfish-textured films. However, Shtein did say he expects that "some of the bottlenecks with the process of developing medicines, as well as administering them, could be resolved using this approach," he says. The UM team is still in the discovery phase with the new material, but Shtein says that if it maintains its funding, its will soon be shooting to present its findings to the Food and Drug Administration. If nanolobe-based drugs do make it past the FDA and on to the market, expect them to be a big hit: Who doesn't want instant relief?