On a bright, sunny afternoon on July 9, a white unmanned air vehicle (UAV), its two 2.75-horsepower engines buzzing, taxied smoothly down a finely mowed field of dark green grass. After a short distance, it lifted off and effortlessly soared to an altitude of about 325 feet. It banked right, then began flying large, lazy circles above the rolling, grassy hills of the Wiltshire Downs in southern England.

After 10 minutes, the drone, which has a wingspan of around 13 feet, gently returned to Earth and taxied back to its ground crew. It was the second of 20 short test flights it made that day. For the first 14, the drone was controlled remotely by a pilot on the ground. The last six tests were on autopilot run from a laptop.

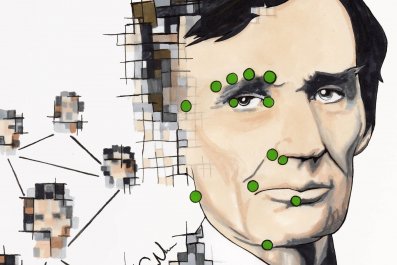

Small UAVs are already a frequent sight in the low altitudes of U.K. airspace, but what made this drone a rare bird was how it came into being: Most of its key parts, including the fuselage and fuel tank, were fashioned in lightweight nylon by a 3-D printer. Three years ago, a team of University of Southampton researchers, led by Jim Scanlan, a professor of aerospace design, scored a world first when they built and flew a UAV constructed entirely from parts made by additive manufacturing, or 3-D printing. That original UAV, four iterations ago, was smaller, with a 4-foot wingspan. Since then, Scanlan's team, armed with a $5 million government grant, has already proved that drones can be designed, built and tested in less than two weeks using additive manufacturing.

Now Scanlan has set his sights on an even larger target. He wants to prove that the 52-pound, 3-D-printed drone that swooped over the wheat fields of Wilshire in July is a prototype for next-generation cargo planes. "I strongly believe that all cargo aircraft will soon be unmanned," he says. More boldly, Scanlan also believes that large cargo planes—assembled from 3-D-printed parts—can soon be plying the skies using inexpensive, off-the-shelf communications technologies, instead of relying on the burgeoning but expensive sense-and-avoid systems the aviation industry is currently testing.

That's a view currently at odds with the thinking of the industry and its regulatory agencies. A spokesman for Britain's Civil Aviation Authority tells Newsweek that no large drones will be permitted to fly in U.K. airspace until they're equipped with avoidance technology. "It won't happen until there's a reliable system," he says.

But to prove otherwise, Scanlan has started a program called HIATUS (Highlands and Islands Aerial Transport Using Unmanned Systems), which he hopes will, within 18 months, use 3-D-printed drones, each about half the size of a small Cessna and flying semiautonomously, to ferry goods to remote islands in Europe that have poor transportation links and are often inaccessible because of fog and bad weather. "Our unmanned aircraft," he insists, "is perfectly happy flying in fog."

Over the past decade, the U.S. military's drone fleet has grown from less than 5 percent of all aircraft to more than 40 percent. So far, militaries have been the biggest developers and users of UAVs. But that's about to change. In September 2015, the U.S. Federal Aviation Administration will introduce regulations allowing for UAVs in civil airspace, and it predicts 10,000 drones will be flying in American skies by 2017. A 2012 report by U.S.-based aviation consultants Teal Group estimated that by 2022, annual spending on UAVs will jump from $6.6 billion to $11.4 billion, for a total of $89 billion over the decade. Initially, in many developed countries small UAVs are likely to be used for border surveillance, policing, monitoring sea-lanes and inspecting farmlands.

But the real economic impact will come once large cargo carriers can go pilotless. The cargo industry is eager to cut fuel costs and reduce its carbon footprint by using planes that are lighter and more efficient. That's why drones could be a welcome development, especially if they can be made more cheaply using 3-D printers and strong but light material like nylon.

Planes without humans aboard don't need expensive, and heavy, life-support systems to keep cabins pressurized. UAVs also take pilot pay out of the equation, and that's the second biggest cost after fuel for commercial aircraft. UAVs are safer, too, Scanlan says. "Most airline crashes now are human errors, so let's get rid of the humans in the cockpit."

The researchers running the Autonomous Systems Technology Related Airborne Evaluation and Assessment (or ASTRAEA) project—a three-year, $106 million effort jointly funded by industry and government that's researching how best to allow UAVs and manned aircraft to share U.K. airspace—couldn't agree more. Last summer, ASTRAEA carried out test flights across Britain using a two-engine Jetstream prop plane that was remotely controlled from the ground (although an onboard human pilot handled the takeoffs and landings). The project leaders are now working with regulatory and standards organizations to craft a regulatory framework.

The problem isn't having robotic planes in controlled airspace, says Lambert Dopping-Hepenstal, ASTRAEA's project director, but flying in the low-altitude "uncontrolled airspace" on the edge of an airfield. "It is more difficult in uncontrolled airspace, where anyone can fly—balloonists, gliders, parachutists—[and] where we now depend on pilot response. You can't put a UAV in that airspace until you prove it is safe." Which is why there's a big push to develop avoidance systems. Dopping-Hepenstal admits that's a major technical challenge, though he thinks it's one that researchers can solve by 2020.

Beyond developing sense-and-avoid technology, it's necessary to figure out how to provide "absolutely secure" communications systems linking ground and plane, he says. Communications between controllers and pilots are currently unsecured, and anyone can listen in. That's fine when it's just oral communication. But that can't be allowed to happen if electronic information is traveling back and forth between the aircraft's autonomous system and the ground-based pilot who has ultimate control. "We cannot risk it being hacked," Dopping-Hepenstal says.

Scanlan, however, claims that "the regulators have got it wrong." Avoidance systems are still far from ready, "and they're a waste of time and too complicated." They're basically cameras, Scanlan notes, but cameras don't work in clouds or fog, "so what's the use of that?" Meanwhile, he says, all commercial planes now use transponders—passive radar systems that enable them to "talk" to each other and avoid collisions in clouds. "Transponders work. They are done and dusted," he says. The better option, he adds, is to require other types of craft, like balloons and gliders, to be fitted with transponders as well.

Scanlan's HIATUS project uses transponder technology on its drones, with a system it calls "airspace multiplexing" added to those aircraft. This means operating its UAVs during low-demand night hours and in poor weather to further reduce the chances they'll encounter other craft.

Scanlan believes that once he's got a small fleet of 3-D-printed drones up and flying safely without sense-and-avoid systems, he'll eventually convince regulators he's right and be able to win approval to fly larger unmanned cargo jets in more populous areas. "The most convincing argument you can put to regulators is, 'We've done 1,000 to 5,000 hours without incident, now let us try this in another area,'" he says.

If he's right, then the leap from the prototype drone his team's been test-flying to full-sized cargo planes ferrying goods worldwide could end up being a relatively short hop.